New tools mark Main Group response to production chain weaknesses

Footwear technology provider Main Group has announced a series of technology solutions that it has developed in response to “weaknesses along the production chain” that it believes the international health emergency has highlighted.

The Veneto-based supplier of direct-injection, soling and other technology said these weaknesses require urgent remedies, including shortening the supply chain, improving efficiency and saving resources. These steps, it said, “are essential for the recovery of the footwear market”.

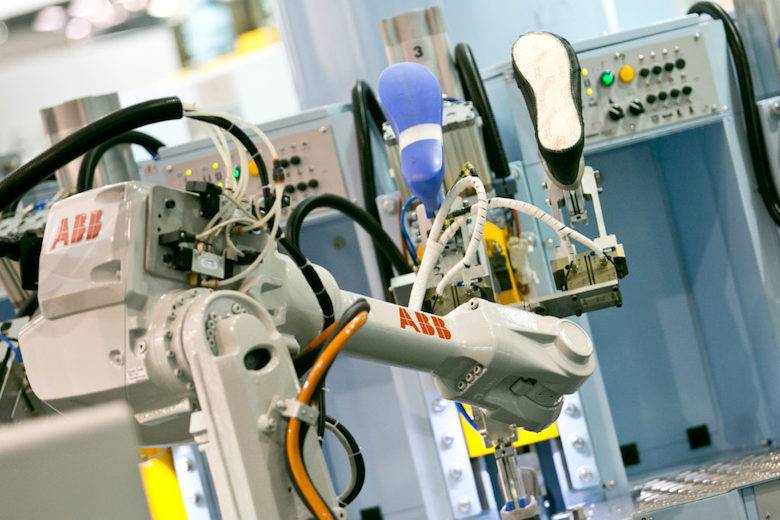

Its response includes a series of tools to improve the efficiency and quality of specific phases of the shoe production process. High-precision carding with automatic change for the processing of all types of leather or synthetic materials is one example. Others are the tailor-made siliconising process for any mould, with automatic mould change and the interconnection of all the stations along the production line.

All of these applications have been designed to improve the quality of finished products, minimising human intervention and improving productivity and replicability, the company said.

It added that the technology can work with new machinery and with equipment already installed. The additions will “immediately improve the quality and efficiency of processes”, it said, calling them steps towards “a smart revolution” that will culminate in the introduction of artificial intelligence in footwear production.